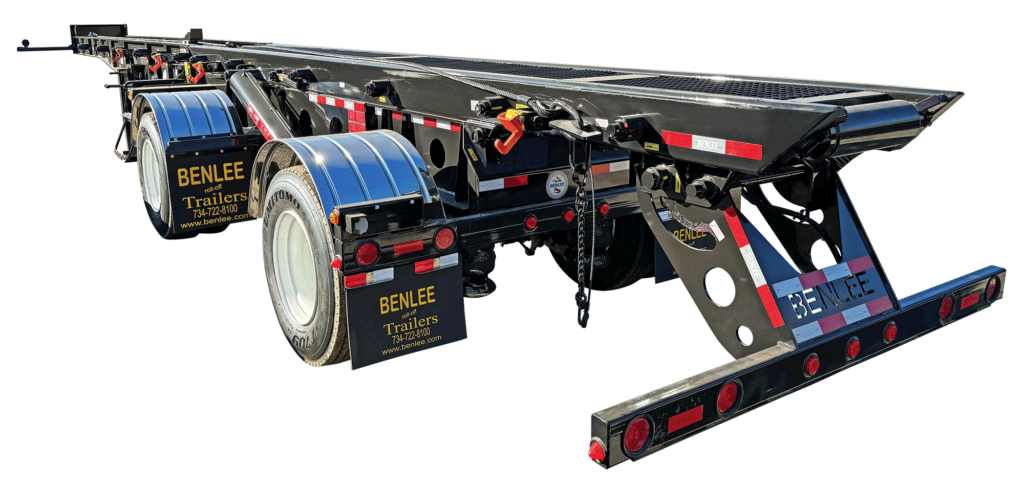

Why BENLEE Is the Ultimate Two-Container Roll-Off Trailer for Long-Distance Environmental Applications

When environmental companies need reliable equipment for long-haul operations, choosing the right trailer matters. For decades, operators have trusted BENLEE Manufacturing to deliver trailers that withstand brutal conditions. From Canadian oil sands to Midwest landfills, and Texas oilfields, BENLEE trailers prove themselves daily. Here’s why BENLEE’s two container roll off trailer is the industry’s best choice for demanding environmental work.

Unmatched Warranty Coverage Demonstrates Confidence: Longest Warranty in the Industry

BENLEE backs every trailer with the industry’s longest frame Warranty in the industry at six years. This guarantee isn’t just marketing talk. It reflects genuine engineering excellence and manufacturing quality. Competitors typically offer shorter warranties because they can’t match BENLEE’s construction standards. Meanwhile, this warranty protects your investment while reducing long-term ownership costs.

Built for Harsh Environments From Day One

Environmental hauling demands equipment that survives extreme conditions. BENLEE trailers excel in the toughest Canadian, Northeast, and Midwest environments. Every hydraulic line receives plating for superior anticorrosion protection and paint adherence. Furthermore, the frame undergoes sandblasting before receiving primer and epoxy coating. This meticulous process creates exceptional durability.

Operators frequently comment on BENLEE’s superior finish. As one satisfied customer noted, “This paint job is better than my car!” After decades of use, BENLEE trailers show remarkably little rust. This longevity proves the value of proper surface preparation and coating application.

Superior Hydraulic Systems Reduce Downtime

BENLEE uses 1-inch steel hydraulic lines instead of the ¾-inch lines found on competing trailers. Additionally, hoses are rated for 3,000 pounds versus the standard 2,000 pounds. These specifications aren’t arbitrary. Larger hoses and heavier-duty lines mean fewer leaks in the field. Consequently, operators experience less downtime and lower maintenance costs.

For environmental companies, downtime equals lost revenue. Therefore, investing in superior hydraulic components pays dividends throughout the trailer’s life. BENLEE’s commitment to heavy-duty hydraulics ensures reliable operation year after year.

Safety Features That Set Industry Standards

Safety remains paramount in environmental hauling operations. BENLEE incorporates multiple exclusive safety features as standard equipment. The trailer includes both hoist-up and tail-up alarms to prevent operator errors. Moreover, 102-inch wide axles provide exceptional stability during loading and dumping operations.

The 48,000-pound straps far exceed the 20,000-pound straps found on competing trailers. This massive strength difference provides critical safety margins when hauling heavy environmental loads. Additionally, wheel bearing heat sensors alert operators to potential problems before failures occur. These sensors help prevent roadside breakdowns and costly repairs.

The wider 102-inch axles with sealed hubs deliver added stability on unstable landfill ground. This design reduces tipping risks when dumping on less stable surfaces. For operators, enhanced stability means greater confidence during every dump cycle.

Planetary Winch Power for Extreme Applications

Environmental hauling often involves challenging loads. Industrial sludge, toxic chemicals, liquid waste, and hazardous solids test equipment limits. BENLEE addresses these challenges with a high-powered Tulsa planetary winch. This severe-duty unit delivers exceptional torque for moving heavy loads.

The planetary design handles muddy, high-stress, and off-road conditions with ease. When containers get stuck or overloaded, BENLEE’s winch keeps pulling. Other trailers might stall under similar conditions. However, BENLEE’s powerhouse winch pulls through consistently.

This severe-duty design makes BENLEE ideal for oilfield applications and toxic waste handling. The winch withstands abusive loading conditions that would damage lesser equipment. For operations requiring raw winching power, BENLEE delivers unmatched performance.

High-Strength Steel Engineering

BENLEE’s frame uses high-strength steel in a carefully engineered design. This approach creates a trailer that’s simultaneously heavy-duty and lightweight. The strength supports the six-year frame warranty while enabling excellent payload capacity.

Low tare weight means operators can legally haul maximum payloads on every trip. This efficiency directly impacts profitability for environmental hauling companies. Furthermore, the high-strength construction ensures long life under abusive stress conditions.

When extreme power and durability are needed, BENLEE delivers. The frame handles industrial strength demands without premature failure. This reliability keeps trailers working instead of sitting in repair shops.

Dozens of Exclusive Features Create Competitive Advantages

BENLEE incorporates numerous exclusive features that competitors simply don’t offer. Dragon, Clement, American Carrier Equipment, and Dentoni lack these innovations. Consequently, BENLEE can confidently claim the safest, highest-uptime, and lowest-cost trailer available.

The exclusive front shuttle system prevents the frequent cable breaking that plagues Dragon trailers. Smooth movement eliminates stress points that cause failures. Similarly, the exclusive rear driver cable return system enhances both speed and safety.

BENLEE uses beckets to hold cables instead of cable clamps. This detail improves reliability while reducing maintenance needs. The 12-inch sheaves exceed the 8 or 10-inch sizes found elsewhere. Larger sheaves reduce cable wear and extend service life.

Grease grooves in sheaves and rollers ensure proper lubrication. This simple feature extends component life while reducing friction. Together, these exclusive features deliver superior uptime and lower operating costs.

World-Class Manufacturing Enables Competitive Pricing

Despite premium features, BENLEE doesn’t charge premium prices. World-class manufacturing techniques make this possible. Great purchasing power reduces component costs significantly. Advanced manufacturing technology improves efficiency throughout production.

A skilled, safety-focused workforce builds every trailer to exacting standards. Almost zero warranty costs demonstrate the quality built into each unit. Furthermore, world-class software controls costs without compromising quality.

This combination allows BENLEE to price trailers competitively for everyone. Large national companies and small startups both benefit from fair pricing. Premium quality doesn’t require premium pricing when manufacturing excellence drives the business.

Ready When You Need It

BENLEE maintains standard design units in stock for same-day shipment. This availability helps operators replace damaged equipment quickly or expand fleets rapidly. You call 734-722-8100 starting at 6:00 AM EST or buy 24/7 at BENLEE’s online parts store. However, customization remains readily available for specific needs.

Different axles, extra axles, custom frames, colors, suspensions, and tire options accommodate diverse requirements. BENLEE has built trailers with up to eight axles for major customers like Republic Industries. This flexibility ensures the right trailer for every application.

Maintenance-Free Sensor Technology

Modern BENLEE trailers incorporate solid-state sensors that require no maintenance. These reliable components monitor critical systems without adding maintenance burdens. The ABS system includes a secondary air filter providing an added 100,000-mile warranty.

Wheel bearing heat sensors provide early warning of potential failures. This technology prevents catastrophic bearing failures that could strand trailers. Consequently, operators enjoy greater peace of mind and fewer emergency repairs.

Standard Features That Exceed Competitors

BENLEE’s standard 10-foot 2-inch spread axles provide exceptional weight distribution. This configuration optimizes tire wear and extends component life. Moreover, BENLEE readily builds other axle configurations for special applications.

The trailer’s industry-leading ability to carry two 23-foot-plus boxes sets it apart. Vacuum boxes, acid tanks, and similar specialized equipment fit easily. This versatility makes BENLEE suitable for diverse environmental applications.

Canadian Market Leadership

BENLEE currently serves as a major Canadian supplier. The tri-axle design with extendable tail meets Canadian SPIF regulations perfectly. This makes BENLEE trailers ideal for challenging oil sands field operations.

Canadian environmental conditions rank among the harshest anywhere. BENLEE’s proven performance in these conditions demonstrates true durability. Operators working in extreme cold, corrosive environments, and rough terrain rely on BENLEE.

Industry-Leading Parts Support

BENLEE operates the industry’s number one online parts store. This resource supports BENLEE trailers plus Dragon, American, Galbreath, and other brands. One-stop shopping for roll-off trailer and truck parts simplifies maintenance operations, including Pioneer, Roll-Rite and more.

Having readily available parts reduces downtime significantly. Operators don’t waste time searching multiple suppliers for needed components. Instead, they find everything at BENLEE’s comprehensive parts store.

The Bottom Line on Ownership Costs

BENLEE trailers deliver the lowest total owning and operating costs available. The combination of durability, reliability, and efficient operation creates exceptional value. Lower maintenance costs, reduced downtime, and longer service life all contribute to profitability.

The six-year frame warranty alone saves thousands in potential replacement costs. Superior components reduce repair frequency throughout the trailer’s life. Maximum legal payloads increase revenue on every trip.

Built for Environmental Industry Demands

Environmental hauling presents unique challenges. Toxic chemicals, corrosive materials, and heavy loads stress equipment constantly. BENLEE specifically designs trailers for these strenuous, abusive environments.

From industrial sludge to hazardous solids, BENLEE handles it all. The planetary winch powers through stuck loads and overloaded containers. Meanwhile, sealed hubs protect bearings from contaminated environments.

Superior paint and coating systems resist chemical attack better than competitors. Plated hydraulic lines withstand corrosive conditions longer. Every design choice reflects understanding of real-world environmental hauling demands.

Conclusion: The Clear Choice for Long-Haul Environmental Work

For long-distance environmental applications, BENLEE trailers deliver unmatched performance. The combination of durability, power, safety, and value creates the industry’s best solution. Exclusive features provide genuine competitive advantages over Dragon, Clement, American Carrier Equipment, and Dentoni.

World-class manufacturing produces premium quality at market prices. The six-year frame warranty demonstrates confidence in engineering excellence. Superior components reduce maintenance costs while increasing uptime.

Whether you operate one trailer or manage a national fleet, BENLEE delivers results. The proven performance in Canada’s harshest conditions speaks volumes. Operators consistently report exceptional longevity and minimal rust even after decades of service.

For environmental companies demanding the best, BENLEE provides the answer. Superior winch power handles the toughest loads with ease. Advanced safety features protect operators and equipment alike. Comprehensive parts support keeps trailers running efficiently.

BENLEE doesn’t just build trailers. They engineer solutions for the environmental industry’s most demanding applications. When long-haul reliability matters most, choose BENLEE.

Greg Brown

greg.brown@benlee.com

734-722-8100